Vibratory Furnace Charger

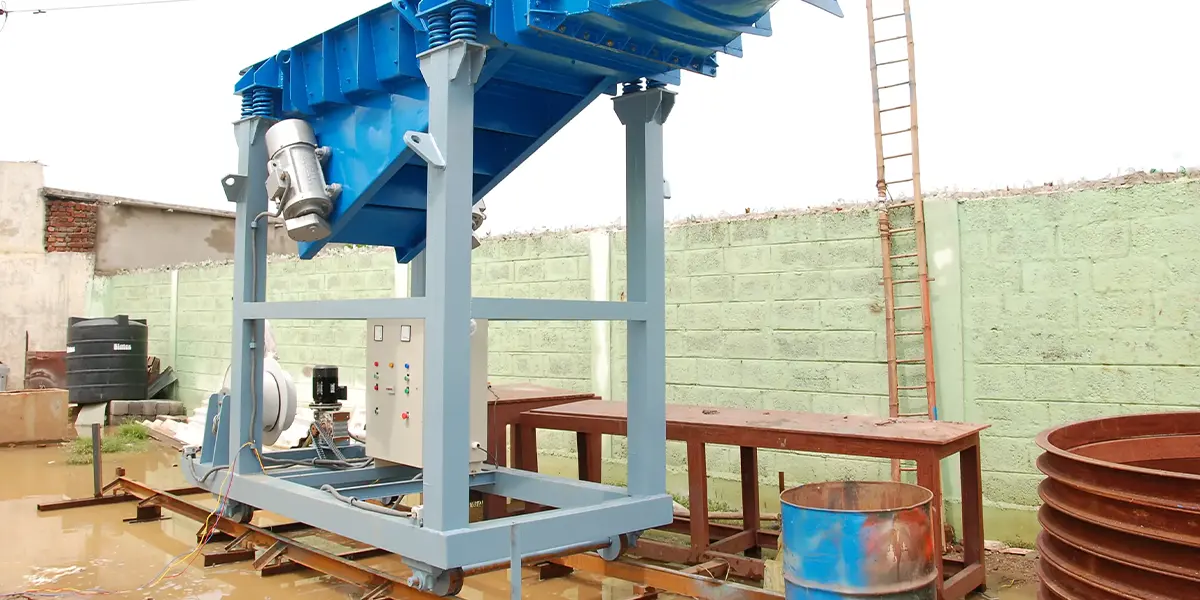

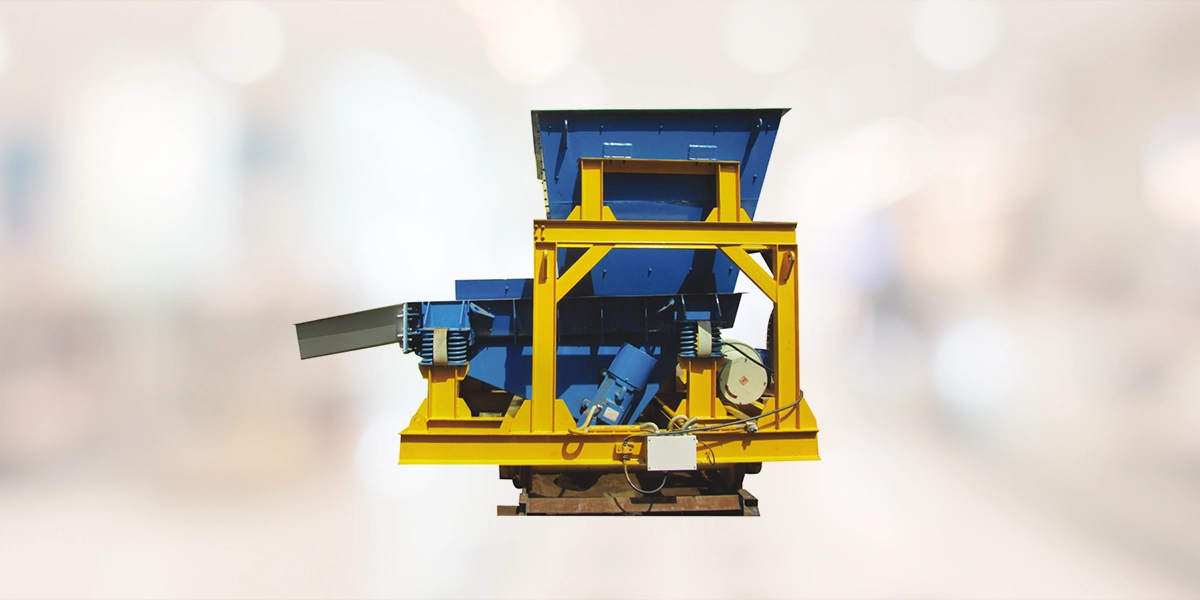

Electro Flux specializes in manufacturing and supplying vibratory furnace chargers, which facilitate rapid and efficient charging of furnaces, optimizing their utilization. The vibratory furnace charger consists of a vibrating feeder mounted on a moving trolley, with a storage hopper positioned above the feeder. The system includes various components, such as a vibrating feeder, storage hopper, moving carriage with driving arrangements, control panel, and optional cable reeling drum or cable drag chain.

Benefits of Vibratory Furnace Chargers:

- Rapid and quick charging of furnaces

- Maximum utilization of furnace capacity

- Enhanced operational efficiency

Components of Vibratory Furnace Chargers:

- Vibrating feeder: Delivers the required charging capacity

- Storage hopper: Provides the necessary capacity for storing material

- Moving carriage with driving arrangements: Enables movement and precise positioning

- Control panel: Operates the system effectively

- Cable reeling drum/cable drag chain (optional): Ensures efficient cable management

Watch Demo

Vibratory Furnace Charger for Effective Material Handling

Electro Flux Equipments provides a high-performance vibratory furnace charger to automate and optimise the furnaces’ charging process with raw materials. Being an innovative solution in industrial foundries, our furnace charger assures smooth, precise, and even material supply with reduced manual intervention and increased overall productivity.

Our vibratory furnace charger is designed to be reliable, safe, and accurate. Its heavy-duty construction and uniform vibration system enable controlled flow of different materials such as metal ingots, scrap, and alloys. This allows charging of the furnace to be done efficiently, minimising downtime as well as material wastage.

Technical Features & Benefits

Electro Flux’s vibratory furnace charger has several technical benefits that make it an industry favourite among modern foundries:

- Precision Vibratory Mechanism: Provides consistent material feed to the furnace, avoiding spillage and overloading.

- High Load Capacity: Designed with heavy loads in mind, allowing seamless operations for massive industrial demands.

- Long Lasting Construction: Constructed using high-strength steel and vibration-free materials for reliable performance over a period of time.

- Adjustable Vibration Settings: Enables calibration of feed speed based on material type and furnace specifications.

- Energy Efficient: Optimised motor design minimises power consumption while delivering superior performance.

Applications Across Industries

Electro Flux’s vibratory furnace charger has several technical benefits that make it an industry favourite among modern foundries:

- Steel and Foundry Industry: Charging furnaces with ingots, scrap, or alloy metals

- Non-Ferrous Metal Processing: Efficient feeding of aluminium, copper, and other non-ferrous metals

- Alloy Production: Consistent charging of materials for homogeneous mixing

- Laboratory and Small-Scale Furnaces: Precise material handling in smaller operations

Its adaptability makes it ideal for both high-volume production facilities and smaller, specialised workshops, giving operators complete control over the charging process.

Customisation and Support

Electro Flux recognises that each foundry has its own requirements. Our vibratory furnace charger can be customised to handle particular types of material, furnace size, and operational sequences. Options are:

- Adjustment of table size and vibration frequency

- Modification of load capacity

- Integration with automated furnace systems

- On-site installation, training, and maintenance support

Our trained engineers guarantee each furnace charger is tailor-made for the client’s unique needs, guaranteeing dependable performance right from day one.

Why Choose Electro Flux Equipments

Electro Flux Equipments is a reliable vibratory furnace charger manufacturer. Here’s why:

- Established record of industrial equipment manufacturing

- Emphasis on accuracy, reliability, and safety

- Flexible solutions for varied material handling applications

- Timely after-sales support and maintenance services

Build Unstoppable Power with Our Lifting Solutions

Check out our wide range of magnetic solutions to find the best fit. Our Team of specialists are here to assist you.

FAQs

Q.How does a vibratory furnace charger work?

A vibratory furnace charger uses controlled vibrations to feed materials into a furnace evenly and efficiently, reducing spillage and ensuring uniform charging.

Q.What are the advantages of using a vibratory furnace charger?

It improves productivity, ensures uniform material flow, reduces manual labour, minimises material wastage, and enhances safety during furnace charging.

Q.What is a furnace charge?

A furnace charge is the quantity of raw material or metal loaded into a furnace for melting or processing.