Vibrating Feeder

Electro Flux specializes in manufacturing and supplying vibratory feeders, which increase bulk handling productivity with variable controlled feed rates. These versatile feeders can handle a wide range of materials, from fine powders to large, coarse particles. The capacities of the vibratory feeders range from 1 Ton to 100 Tons per hour, depending on various factors such as drive unit location, material characteristics, density, length and width, liner type, feeder installation, skirt boards, and hopper transitions.

Get in touch with Electro Flux Equipments to upgrade your feeding system. Require a standard vibrator feeder or a vibratory feeder made especially for particular materials? We can help you optimise flow, reduce waste, and increase production efficiency.

Key Features of Electro Flux Vibratory Feeders:

- Variable controlled feed rates

- No mechanical parts to wear out

- Long service life of electrical components

- Low energy consumption

Types of Feeding Mechanisms

- Electromagnetic vibratory feeder – Ideal for light powders and fine materials that require precise, controlled flow.

- Mechanical (brute-force) vibro feeder – Used for heavy bulk materials at high rates, using unbalanced weights.

- Bowl feeder (vibratory bowl) – Used for aligning minute pieces in automatic operations, widely used in the automotive and electronics industries.

Key Benefits

- Uniform and Regulated Feed

Our vibratory feeder features even distribution across the tray to optimise downstream processes. Vibration is modifiable so that you can tailor the vibrator feeder output based on application requirements.

- Reduced Maintenance

Feeder trays will not rip like conveyors and material spillage is minimised. Electromagnetic systems offer clean, low-maintenance operation.

- Designed for Any Material

The vibrating feeder unit can be used to handle anything from heavy aggregate to fragile powders, and flow and vibration levels can be controlled accurately.

- Anti-Bridging Action

Feeder vibration prevents clogging and bridging, which will stop material flow constantly.

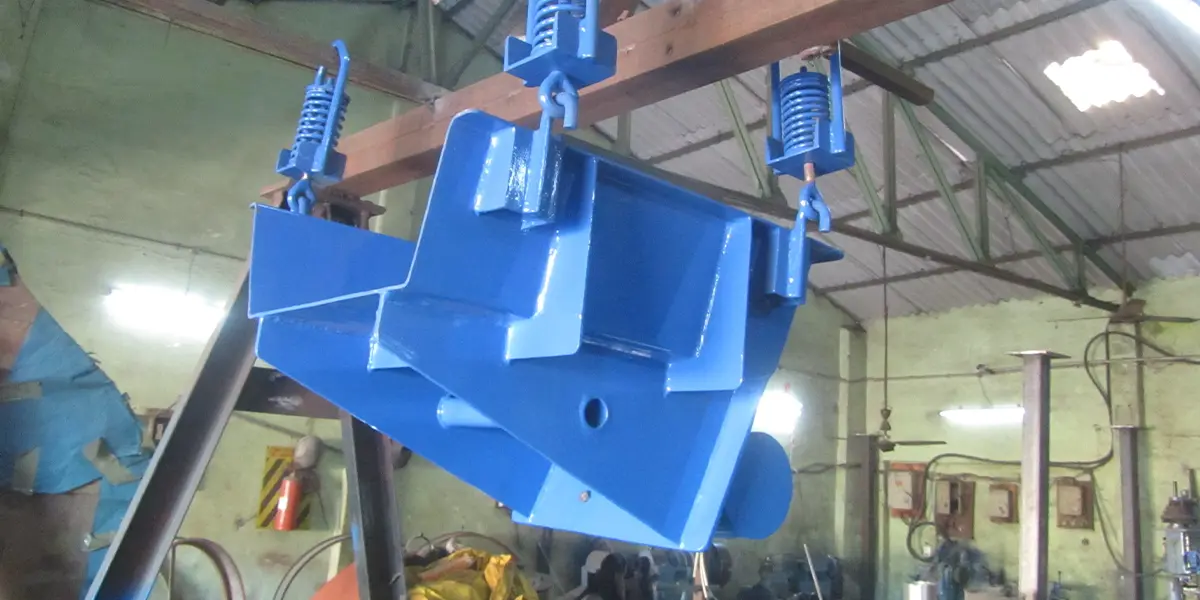

Flexibility in Custom Engineering & Design

Tray size and shape: Can be made to fit any hopper or bin

- Mounting types: Spring-mounted or coil-supported

- Drives: Electromagnetic or mechanical

- Control panels: Manual or PLC-based

- Wear liners and surface coatings may be supplied

- Optional accessories: Dust shrouds, grizzly bars, guards

Applications Across Industries

- Mining and aggregate feeding

- Recycling and bulk waste material transfer

- Food, pharma, and chemical dosing systems

- Automotive parts orientation and packaging lines

Why Electro Flux?

- Industrial-quality, long-lasting components

- Consistent and reliable performance

- On-site support and commissioning

- Designed to integrate into current systems

- Competitive prices and local availability

Electro Magnetic Feeder

The Electro Magnetic Feeder is designed to increase bulk handling productivity with variable controlled feed rates. It can handle a wide range of materials, from fine powders to large, coarse particles. The feeder capacities range from 1 Ton to 100 Tons per hour, and its durable design ensures long-lasting performance.

Electro Mechanical Feeder:

The Electro Mechanical Feeder with unbalanced motor drives provides an economical conveying solution for all bulk materials. Vibratory feeders have low energy consumption compared to other conveying methods. The capacities of the electro mechanical feeders range from 1 Ton to 100 Tons per hour.

The vibration is achieved through the eccentric movement of the unbalanced weights mounted on each side of the motor. The twin motor vibrator drives, arranged for counter-rotation, provide a linear vibratory action that conveys the product across the vibrating surface.

Effective Heavy-Duty Vibrating Feeder System

Electro Flux Equipments manufactures and provides heavy-duty vibrating feeders and vibro feeder systems engineered with precision material handling in mind. Whatever your need for controlled feeding out of silos, hoppers, or trucks, our vibratory feeder solutions provide smooth, consistent flow. We, being the best vibrating feeder manufacturers, tailor each system to your specifications—material type, flow rate, installation conditions, and integration requirements.

How Our Vibratory Feeder Works

Our vibrating feeder system utilises electromagnetic or mechanical vibrators to transfer controlled vibration to the feeder tray. Lift and propulsion forces, when combined, transport bulk materials along the trough with incremental accuracy. The frequency and amplitude may be adjusted to suit different material properties. This principle is utilised extensively in industrial feeders to prevent bridging and ensure uniform flow.

Watch Demo

Build Unstoppable Power with Our Lifting Solutions

Check out our wide range of magnetic solutions to find the best fit. Our Team of specialists are here to assist you.

FAQs

Q.What are the different types of feeders?

Common types include vibrating feeders, apron feeders, belt feeders, screw feeders, and grizzly feeders.

Q.What does a vibrating feeder do?

A vibrating feeder regulates and transfers bulk materials evenly from a hopper to processing equipment.

Q.What is the use of a feeder machine?

A feeder machine ensures controlled, consistent material flow, reducing blockages and improving efficiency in production lines.

Q.What is a vibrating feeder in mining?

In mining, a vibrating feeder transports ores and aggregates to crushers or screens while separating fine materials.

Q.What is a vibro feeder?

A vibro feeder is another term for a vibrating feeder that uses vibration to move and control the flow of bulk materials.